Microbial Fermentation Technology: Revolutionizing Biotechnology and Industry

Jan 29, 2025

Table of Contents

Microbial fermentation technology is a cornerstone of modern biotechnology, playing a vital role in various industries, from pharmaceuticals and agriculture to food production and environmental sustainability. By leveraging the natural metabolic processes of microorganisms, fermentation has evolved into a powerful tool that supports the production of a wide array of bio-based products.

What is Microbial Fermentation?

Microbial fermentation is a biochemical process in which microorganisms, such as bacteria, yeast, and fungi, break down organic substrates like sugars, starches, or fats to produce valuable metabolites. During fermentation, microorganisms convert carbohydrates into products like alcohol, acids, gases, and other bioactive compounds, which are essential in industries ranging from food and beverage production to pharmaceuticals and biofuels.

Downloads

Article in PDF

Recent Articles

- Takeda and AC Immune’s Alzheimer’s Deal; Eli Lilly’s Donanemab FDA Review; Bristol Myers Sq...

- Social Behavior Loss Observed in Gene-edited ants through CRISPR

- Lyfgenia or Casgevy: Who Will Lead the Sickle Cell Disease Treatment Space?

- Business Cocktail

- AbbVie, Sofinnova back; Gilead, Kite ink; Biogen aims filing; Reversing diabetes

The versatility of microbial fermentation makes it a critical tool in biotechnology. Through this process, microorganisms are utilized to produce a wide array of compounds, including antibiotics, vitamins, enzymes, and biofuels. This biological production method has been refined over centuries, with significant advancements in modern biotechnology. Today, scientists can genetically engineer microorganisms to optimize fermentation processes, enhancing yields, improving efficiency, and enabling the production of high-value substances that meet global industrial demands.

Types of Microbial Fermentation

Microbial fermentation processes are categorized into two main types based on the presence or absence of oxygen: aerobic fermentation and anaerobic fermentation.

Aerobic Fermentation: Aerobic fermentation occurs in the presence of oxygen, where microorganisms utilize oxygen to break down organic substrates like sugars, resulting in the production of energy-rich compounds such as biomass, organic acids, and certain high-value products. This type of fermentation is commonly used for the production of products such as amino acids, antibiotics, and vitamins, as the presence of oxygen allows for more efficient metabolic activity and higher product yields.

Anaerobic Fermentation: Anaerobic fermentation takes place in the absence of oxygen, where microorganisms rely on alternative pathways to metabolize substrates. This type of fermentation is crucial for the production of biofuels like ethanol and organic acids such as acetic and lactic acid. Anaerobic fermentation is also employed in industrial processes where oxygen can inhibit the growth of specific microorganisms, such as in the production of butanol, bioethanol, and various fermented food products. These two types of fermentation offer diverse applications and are fundamental to the biotechnological industries, each optimized for different end products and process requirements.

Key Microorganisms Used in Fermentation

The choice of microorganisms in fermentation processes is crucial for achieving the desired product. Yeasts, particularly Saccharomyces cerevisiae, are among the most widely used microorganisms in the food and beverage industry. Yeast is essential for the production of alcoholic beverages like beer, wine, and spirits through the fermentation of sugars into ethanol and carbon dioxide. Additionally, yeast plays a significant role in the production of bioethanol, a key biofuel. Beyond alcoholic beverages, Saccharomyces cerevisiae is also used in baking for leavening bread by producing carbon dioxide, which causes the dough to rise. Yeasts are also employed in the production of organic acids, such as citric acid, which is commonly used as a preservative and flavoring agent in food products.

Bacteria also play a pivotal role in fermentation processes. Escherichia coli (E. coli) is one of the most well-known bacterial strains used in industrial fermentation, particularly in the production of recombinant proteins like insulin, growth hormones, and vaccines. E. coli is highly versatile due to its ability to grow rapidly and its well-understood genetic makeup, making it a preferred microorganism for genetic engineering. Lactobacillus species, another key group of bacteria, are vital in the dairy industry for producing products like yogurt, cheese, and kefir. These bacteria ferment lactose into lactic acid, contributing to the tangy taste and preserving the product. Additionally, Lactobacillus is used in probiotics, which are beneficial for gut health, demonstrating the versatility of bacteria in various biotechnological applications.

Fungi (Aspergillus species) are used to produce a variety of enzymes, such as amylases and proteases, which are essential for various industrial applications, including food processing and detergent manufacturing.

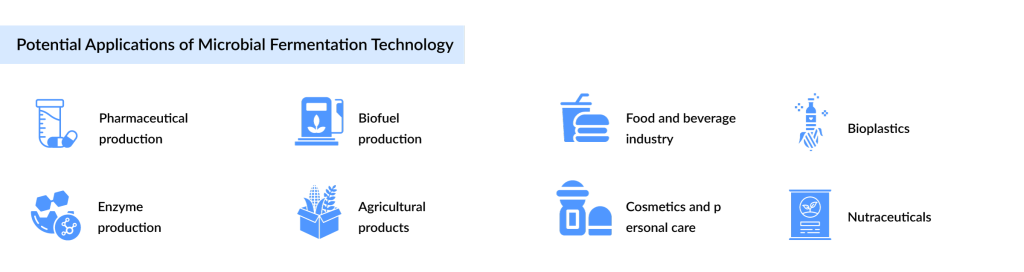

Applications of Microbial Fermentation Technology

In pharmaceuticals and healthcare, microbial fermentation is essential for producing a wide range of life-saving drugs and biopharmaceuticals. Antibiotics such as penicillin and cephalosporins are produced through the fermentation of fungi like Penicillium species. Additionally, microbial fermentation enables the production of recombinant proteins, such as insulin, growth hormones, and monoclonal antibodies. With advancements in genetic engineering, microbes are now also used to manufacture vaccines, immunotherapies, and other bioactive compounds that treat diseases and support medical advancements, making fermentation a cornerstone in modern healthcare.

In food and beverage production, fermentation is central to the creation of staple products like bread, cheese, yogurt, beer, and wine. Yeast, especially Saccharomyces cerevisiae, is widely used to ferment sugars into alcohol and carbon dioxide, critical in the brewing and baking industries. Fermentation not only enhances the taste, texture, and preservation of these foods but also increases their nutritional value, particularly through the production of vitamins, minerals, and probiotics. The process can also help preserve seasonal crops and produce unique flavors that contribute to the diversity of global cuisines.

Biofuels and energy production are another area where microbial fermentation technology is making a significant impact. The fermentation of biomass by microorganisms such as yeasts and bacteria leads to the production of bioethanol, a sustainable alternative to fossil fuels. Bioethanol is commonly used as a fuel additive in gasoline, while more advanced fermentation techniques are being developed to produce other biofuels like butanol and biodiesel. As the world seeks alternatives to traditional energy sources, microbial fermentation offers a renewable and environmentally friendly solution to meet the growing demand for clean energy.

Microbial fermentation is also important in agriculture, particularly in the production of biofertilizers, biopesticides, and animal feed additives. Fermentation-derived products like amino acids and plant hormones can be used to enhance crop yields and soil health. Additionally, fermentation is used to produce probiotics for animal health.

Furthermore, fermentation technology is contributing to environmental sustainability by enabling the production of biodegradable plastics, reducing waste, and transforming agricultural residues into valuable bio-based products. Moreover, fermentation can be used in the bioremediation of pollutants, helping to clean up contaminated environments.

Advancements in Microbial Fermentation

Recent advancements in microbial fermentation have significantly enhanced the efficiency, scalability, and versatility of fermentation processes. One of the most impactful developments is the application of genetic engineering and metabolic engineering, which allow scientists to optimize microorganisms for the production of specific compounds. By manipulating the genetic pathways of microbes, researchers can increase the yield of desired products, such as biofuels, antibiotics, and specialty chemicals, while reducing by-products and waste. The advent of synthetic biology has further accelerated these advances, enabling the creation of entirely new metabolic pathways in microorganisms, and expanding the range of products that can be synthesized through fermentation.

Another breakthrough is the integration of CRISPR/Cas9 gene-editing technology into fermentation processes. This tool allows for precise, targeted modifications of microbial genomes, leading to improved strain performance, enhanced resistance to environmental stresses, and optimized production of bio-based products. Additionally, innovations in bioreactor design have made it possible to scale up fermentation processes more efficiently. The use of continuous fermentation systems and large-scale bioreactors has enabled the production of high volumes of bio-based products, meeting the increasing demand across various industries, from food production to pharmaceuticals. These advancements not only improve the productivity of fermentation but also reduce production costs, making microbial fermentation more economically viable on a global scale.

Prominent Companies Working in the Microbial Fermentation Technology Market

Several leading companies are at the forefront of the microbial fermentation technology market, contributing to the development of innovative solutions across various industries. DSM Biotechnology is one of the major players, specializing in the production of enzymes, vitamins, and probiotics through microbial fermentation. With its extensive portfolio of fermentation-based products, DSM serves multiple industries, including food and beverage, agriculture, and healthcare. The company continues to invest in advanced fermentation technologies to improve production efficiency and sustainability.

Another key player is Novozymes, a global leader in industrial biotechnology, which focuses on providing enzyme solutions for a wide range of industries, including bioenergy, agriculture, and food. Novozymes’ expertise in microbial fermentation has enabled the company to develop innovative enzyme products that optimize fermentation processes and improve overall production yields. By leveraging advanced research in microbial strain development and metabolic engineering, Novozymes is continuously enhancing the scope and efficiency of its fermentation solutions.

Lonza Group is another prominent company that offers fermentation-based services for the pharmaceutical and biotechnology industries. Lonza specializes in the production of biologics, including monoclonal antibodies and cell therapies, using microbial fermentation techniques. With a robust global presence and a commitment to enhancing bioprocessing capabilities, Lonza plays a crucial role in advancing microbial fermentation technologies, particularly in the biopharmaceutical space. These companies, alongside others, are driving the growth of the microbial fermentation technology market, shaping its future with continuous innovation.

The other key companies dominating the microbial fermentation technology market include Biocon Ltd., BioVectra Inc., Danone UK, F. Hoffmann-La Roche AG, TerraVia Holdings, Inc., BIOZEEN, and others.

Future Trends and Challenges in Microbial Fermentation Technology

The future of microbial fermentation technology is driven by several emerging trends, particularly in the areas of precision fermentation and waste-to-value conversion. Precision fermentation involves using genetically engineered microorganisms to produce high-value and complex compounds that were previously difficult to synthesize, such as alternative proteins, specialty chemicals, and even rare pharmaceutical compounds. This approach has the potential to revolutionize industries like food production, where bio-based alternatives to animal-derived products could help address global food security and sustainability concerns. Additionally, waste-to-value fermentation is gaining traction, where agricultural and industrial waste are converted into valuable products like biofuels, bioplastics, and organic acids. This trend supports the circular economy by turning waste into resources, reducing environmental impact, and contributing to sustainable practices across various sectors.

Despite the promising advancements in microbial fermentation technology, several challenges remain. One major obstacle is the scalability of microbial fermentation processes, particularly when transitioning from laboratory-scale production to large-scale industrial applications. Ensuring that fermentation systems remain efficient, cost-effective, and sustainable at scale is a complex challenge that requires further innovation in reactor design, process optimization, and raw material sourcing. Additionally, regulatory hurdles, particularly regarding the safety and approval of genetically engineered organisms, pose a challenge to the widespread adoption of precision fermentation technologies. As the demand for bio-based products grows, striking a balance between innovation, scalability, and regulation will be crucial for the continued success and expansion of microbial fermentation technologies.

Downloads

Article in PDF

Recent Articles

- Notizia

- Lyfgenia or Casgevy: Who Will Lead the Sickle Cell Disease Treatment Space?

- A CRISPR WAY TO USE STEM CELLS

- CAR-T Phase I trials; ContraVir Announces; Merck acquired; Excision BioTherapeutics bags $10M

- Inozyme Raises $67M; Shanghai Miracogen partners with Synaffix; EdiGENE raises $15M; Antengene an...